MPI 11-3/4" - 298mm Dia. 0" Dish Black Suede With Orange Stitching Extreme Ergonomic Steering Wheel

Call us for current pricing and availability

Sold As:

One MPI Racing Wheel

Part Number: MPIDRG212

MFG Number:

MPI-DRG2-12

California Prop 65 Warning: This item may cause cancer or reproductive harm. For more info visit p65warnings.ca.gov The above image is a representation of this item. Actual item may vary. If it's crucial to what you're working on, call the store at 951-737-RACE, and one of our sales reps will be happy to email you a current photograph.

California Prop 65 Warning: This item may cause cancer or reproductive harm. For more info visit p65warnings.ca.gov The above image is a representation of this item. Actual item may vary. If it's crucial to what you're working on, call the store at 951-737-RACE, and one of our sales reps will be happy to email you a current photograph. Product Information:

Today's off road racers need their controls at their finger tips, but sometimes the PTT push to talk buttons are in the most uncomfortable position. MPI has the best solution for your buttons and indicator lights. These wheels have four 5/8" slots, two 15/32" slots and four 15/32" round holes. The round holes can be drilled to 1/2".

This extreme ergonomic design allows you to keep a firm grip on your steering wheel at all times, while still being able to reach your most crucial controls.

It is extremely light weight at only 1.15 lbs, because if off-road racing, every ounce counts.

This extreme ergonomic design allows you to keep a firm grip on your steering wheel at all times, while still being able to reach your most crucial controls.

It is extremely light weight at only 1.15 lbs, because if off-road racing, every ounce counts.

SPECIFICATIONS:

Made in ItalyMPI Part Number: MPI-DRG2-12

Outside Diameter: 11-3/4 Inches / 298mm

Weight: 1.15 lbs

Dish Depth: 0" (flat) from mounting surface to back edge of wheel

Grip Material: Highest quality suede

Grip: Extreme ergonomic grip

Frame Material: Aluminum

Bolt Pattern: Standard 5 Bolt

Uses: Off Road Racing / Pro Stock / Drag Racing / SXS / Drifting

MPI DIFFERENCE: CONSTRUCTION METHOD

Most other manufacturers look at maintaining commonality between all products in order to keep prices down. At MPI they look at how to build the best products and give their customers the best value.WHY DOES MPI USE A U CHANNEL AND DOUBLE RIVETS?

At MPI they could have cut some corners and welded their channel instead of creating a jig that precisely guides their rivets inserts. But they didn't because they don't think that is the BEST way to build a steering wheel.Would it have been less expensive? Obviously it takes seconds to weld a steering wheel against the 15 minutes to do the MPI process but we think that is way better!

Max Papis wanted to build the lightest possible product (light = fast in race cars) but still maintaining a top level of safety and deformation under impact. After long months of R&D the MPI 2 rivet winged spoke technology was born.

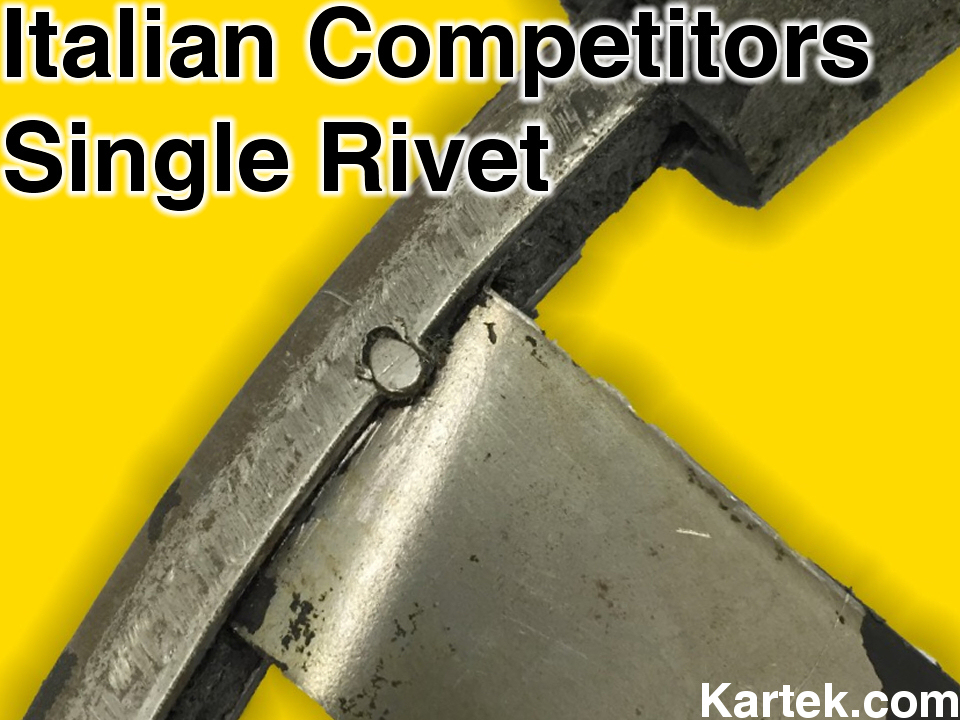

Just because a competitor's wheel cost more doesn't necessarily mean you're getting a better product. Other Italian manufactured wheels use a single rivet construction. And though this is far superior than the Taiwan alternative that is welded, you'll notice that the rivets on other brands of steering wheels are never in the same place and there's only one rivet per spoke.

In the steering wheel history using the U channel and rivets construction has been the standard in the industry for many years. Some overseas companies like to weld their spokes to the U Channel. Why is it that MPI doesn't weld their spokes? Several generations of experience that sent them the message that any hard spot on a circular surface that needs to deform under impact will never deform.

Related Parts

MPI Max Papis Innovations Steering Wheels Double Sided Suede Leather Steering Wheel Brush

In Stock

Price: $19.00

Joes Racing Products Billet Aluminum Clamp-On Steering Wheel Hook For 1-1/2" Diameter Tubing

In Stock

Price: $18.95

Joes Racing Products Billet Aluminum Clamp-On Steering Wheel Hook For 1-3/4" Diameter Tubing

In Stock

Price: $18.95

K-Four 15-100 Sand Sealed Push Button Switch For Ignition Or Horn With #8 Screw Terminals

In Stock

Price: $11.20

Kartek Off-Road Center Aluminum Cap For The Anodized Black Grant Steering Wheel Adapter

In Stock

Price: $11.99

Sweet Steel 3 Bolt Grant / MPI Pattern Steering Wheel Quick Disconnect For 3/4" Steering Shaft

In Stock

Price: $114.91

Sweet Red Anodized Aluminum 3 Bolt Grant / MPI Pattern 3/4" Steering Wheel Quick Disconnect

In Stock

Price: $114.91

Sweet Black Anodized Aluminum 3 Bolt Grant / MPI Pattern 3/4" Steering Wheel Quick Disconnect

In Stock

Price: $114.90

MPI Black Anodized 3 Bolt Grant / Joes Racing / MPI Pattern 3/4" Steering Wheel Quick Disconnect

In Stock

Price: $159.00